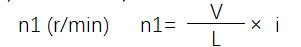

(1). Confirming Required Input rpm

Determine the required input rpm, using the required screw shaft speed.

n1 :Input rpm r/min V :Screw Shaft Speed mm/min L:Screw Lead m R :Gear Ratio

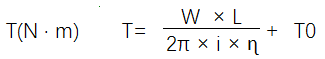

(2). Verifying Required Input Torque

Calculate required input torque.

T:Required Input Torque N・m W:Lifting Load N R:Screw Lead m π:Circular Constant 3.14

R:Gear Ratio η:Starting Efficiency To:No-load torque

For screw lead, gear ratio, starting efficiency and No-load torque, see screw jack specification. Take caution in selecting screw units.

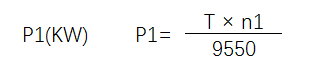

(3). Verifying Input Capacity

P1: Required Input Power T: Required Input Torque N・m n1: Input rpm r/min

2: Screw Jacks General Notes:

(1). Carefully consider jack ratings before making a selection. Make sure that all anticipated loads, whether static, dynamic or shock,

fall within the rated capacity of the jack at reasonable safety levels.

(2). Carefully consider the combination of screw shaft rpm and rated load. Also, take extra care in verifying rated buckling load,

and shaft rpm. Exceeding the data provided in this catalog can cause major damage to the system.

(3). Confirm that the operating temperature of the jack is within −15~80℃. To measure, check the surface temperature of input shaft

(or nut, if used). Make sure that all rotating parts are completely stopped before proceeding to measure.

(4). Do not exceed the maximum rpm of 1500/min.

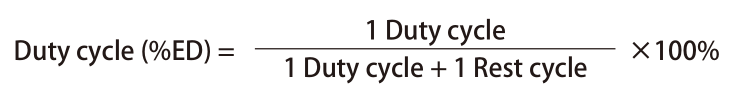

(5). Continuous operation is not possible. Duty cycle at 30 minute intervals for SJW is within 20% ED, SJB is within 30% ED.

(6). Be sure not to exceed the maximum input torque for multiple jack systems by verifying the rated input torque for each jack.

(7). Activating torque should be maintained at 200% above the required torque.

(8). If operating in freezing temperatures, a change in viscosity may reduce the efficiency of the grease. Set the drive unit so as to

accommodate this change.

(9). Although SJW is equipped with a self-locking device, vibration and shock may affect its efficiency, in which case a brake unit is

required. Because of their extremely high efficiencies, SJB must have sufficient brake units that over power their holding torques.

(10). Evaluate operating environment based on the following:

Location Indoors where rain and moisture are not present

Room Condition Dust Volume - Normal

Ambient Temperature -15℃ to 80℃ (See General Notes No.3)

Relative Humidity 85% or less (no dew condensation)

(11). When dust level is high, protect shaft with a bellows.The bellows, which are not water-proof, do not prevent external water from entering and grease in the jack from penetrating to the outside.(For outdoor use, place a cover to protect jack from factors such as rain and wind).

(12). When the screw jack is working, artificial forced shutdown should not be conducted, otherwise will make the screw jack received badly damaged condition.

(13). If you use a special environment, please contact our engineers.

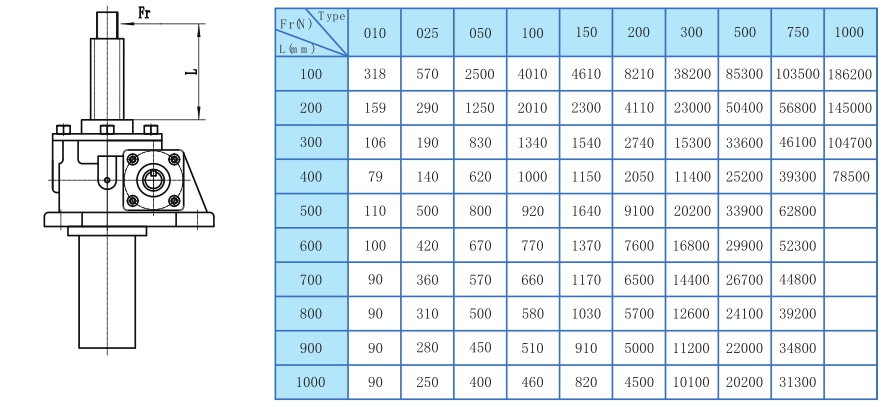

3: Screw Jack Lateral Force

Usually, Screw Jack only lift axial load,any lateral force will make the screw jack’ working life become shorter. When having lateral force, we advise to use an external guide rail.

Allowable Side Load

If side load applies, m ake consideration so that it does not directly apply the jack by installing a guide as show n below .

4: Bevel Gearbox Structures

Bevel Gearbox internal structure: Spiral bevel gears are vertical mounted, right angle or 90 degree to change transmission directions. SIJIE alloy steel spiral bevel gears is case-hardened, and it is of high rigidity and wear resistance.

5: Screw Jack Applications Field

*Stamping fastening device lifting platform, rolling devices, Test instrument lifting platform.

*Flapper adjustments, Transport pipes or plate position adjustment.

* Adjustment thin film thickness of plastic machine.

*Height adjustment of roller systems on a conveyor system.

*Opening and closing of high temperature furnaces

* Adjustment the height of plastic containers blown machinery mound

* De molding of cast concrete models or molds.

* Lifting stage, Adjustment the height of Operating table and swimming pool.

* Lifting and lowering of Sluice gates

* Adjustment of satellite dishes. Adjustment for solar plant stand